Servo motor is a common type of precision control equipment in the field of industrial automation. It achieves high-precision control of the output shaft position, speed and torque through precise control of electronic components. In servo motors, there are many different types of electronic components that play a key role. Common electronic components and their applications in servo motors will be introduced below.

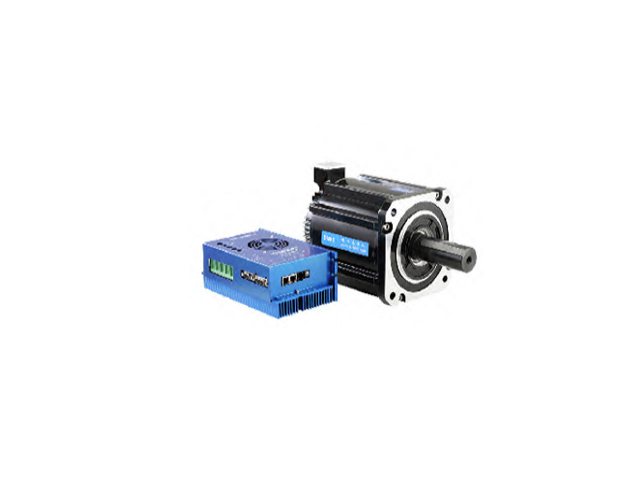

1. Servo drive

The servo driver is the core component of the servo motor system. It is responsible for receiving control signals and converting them into motor drive signals to control the movement of the motor. Servo drives usually include modules such as power amplifiers, current controllers, speed controllers, and position controllers. They achieve high-precision motion control of the motor by precisely controlling the current, speed, and position of the motor.

2. Encoder

The encoder is an important sensor in the servo motor for feedback of motor position information. It can convert the actual position of the motor into a digital signal and feedback it back to the control system to achieve closed-loop control. In servo motor systems, absolute encoders or incremental encoders are usually used to monitor the position, speed and acceleration of the motor in real time, thereby achieving high-precision control of the motor position.

3. Controller

The controller of the servo motor system is responsible for generating control signals and performing closed-loop control of the motor's movement. The controller is usually composed of a microprocessor, digital signal processor (DSP) or a dedicated motion control chip. It can receive feedback signals from the encoder and generate motor control signals based on the control algorithm to achieve control of the motor position, speed and torque. precise control.

4. Power module

The power module in the servo motor system is responsible for providing stable voltage and current to the motor and driver. Power modules usually include DC power supply, three-phase AC power supply, regulated power supply, etc. It can provide various voltages and currents required for motor operation, monitor and protect the power supply, and ensure the stable operation of the servo motor system.

5. Communication interface module

Servo motor systems usually need to communicate with host computers or other devices to achieve functions such as remote monitoring, parameter setting, and data transmission. The communication interface module can be compatible with different communication protocols and interface standards, such as serial port, Ethernet, CAN bus, etc., thereby realizing data exchange and control command transmission between the servo motor system and external devices.

6. Protection circuit

The protection circuit in the servo motor system is responsible for monitoring and protecting the motor and driver to prevent equipment damage due to overload, overvoltage, overcurrent and other abnormal conditions. The protection circuit usually includes overvoltage protection, overcurrent protection, overheating protection and other functions. It can detect and handle abnormal situations in a timely manner to ensure the safe operation of the servo motor system.

In short, the electronic components in the servo motor system play a vital role. Together, they constitute the core components of the servo motor system, providing high-precision and high-reliability motion control capabilities for the industrial automation field. With the continuous development of industrial automation, electronic components in servo motor systems are also constantly innovating and upgrading to meet the increasing needs for control accuracy, communication speed and reliability.

If you need to purchase electronic components, apply for sample testing, BOM distribution, etc., please contact us via the following email address: